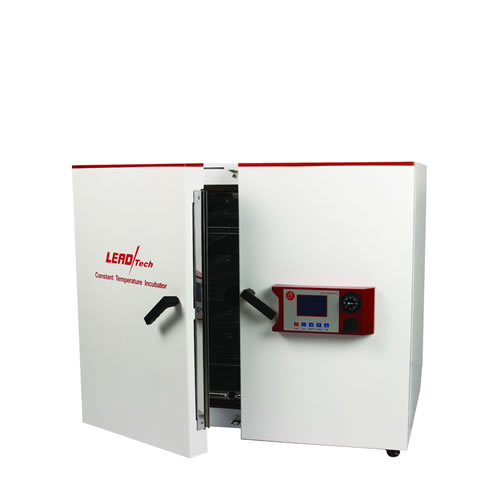

Drying Oven(N)

Application:

The drying oven is a commonly used instrument, and primarily used for drying the sample, and can also provide the required test temperature environment. It is used in chemical engineering, electronics, foundry, automobile, food, machinery and other industries.

1.User-friendly design:

LCD displays the content necessary for experiments including device parameters, operation process and alarm information.

Large rounded mirror, stainless steel liner design: the liner is constructed of SUS304 stainless steel, which effectively reduces dirt residual and microbial growth on the wall and facilitates user’s daily cleaning and maintenance of the equipment.

Vertical lock bar linkage locking device: simple handle rotation, effectively locking the outer door; handle swing range and tightness designed in light of human customary manner, facilitating smooth use of equipment by the user.

2.Safety performance

Double safety early-warning system: the equipment is fitted with an electronic safety warning device and a mechanical self-contained temperature limiter, which effectively prevent abnormal operation from causing the failure of experiments due to the sudden malfunction of the equipment.

3.Performance description

Internal circulation natural wind guide structure: according to the principle of natural heat flow, in cooperation with the box wall wind guide hole, a convection of hot air circulation is formed within the chamber to ensure the accurate uniformity control of temperature.

Inner chamber preheating technology: before circulation air flow comes into the chamber, it will be adequately heated in the preheating layer of the box, and after achieving the proper temperature, be sent into the chamber, effectively lowering the volatility of temperature.

Shell-chamber thermal insulation design: between the chamber and shell casing, arrange a thermal insulation wind guide layer, and by using the heat cycle mechanism, effectively control heat leakage and solve overheating problems of the shell.

Independent electric throttle switch: the device is equipped with a manual electric throttle switch. To meet a variety of culture needs, the user can manually adjust the gas flow within the box.

Remote equipment control: the equipment is connected to a computer through RS485 interface, and its operation is controlled through remote software.

4.Parameters:

|

Model

|

LT-DBX23N/60N/120N/220N/450N

|

|

Temperature

|

Temperature range

|

RT+5℃~300℃

|

|

Uniformity range (50 ℃)

|

±1.0℃

|

|

Uniformity range (100 ℃)

|

±1.5℃

|

|

Fluctuation range

|

±0.1℃

|

|

Process control

|

Process setting

|

10 phase 999 round

|

|

Sensor

|

Temperature sensor

|

PT100

|

|

Electrical indicator

|

Supply voltage

|

AC 220V 50Hz(LT-DBX450N-- 380V)

|

|

Input power

|

200W/300W/400W/650W/850W

|

|

Specifications

|

External dimensions (mm)

|

474×565×557

634×630×622

834×675×702

968×770×880

1234×840×1080

|

|

Liner size (mm)

|

240×290×330

400×375×400

600×417×480

734×500×600

1000×563×800

|

|

Volume

|

23L/60L/120L/220L/450L

|

|

Standard Shelf

|

2/2/3/3/3

|

|

Material

|

Casing material

|

Q235A cold rolled steel

|

|

Liner material

|

SUS304 stainless steel

|

Note: All technical data are measured on standard equipment at an ambient temperature of 25℃, relative humidity of 70% and voltage fluctuation of ±10%, and the door opening temperature and humidity are based on the recovery of 98% of the original state. The Company reserves the right to change technical specifications.